Please select language

Inquiry

Tel

Request A Quote

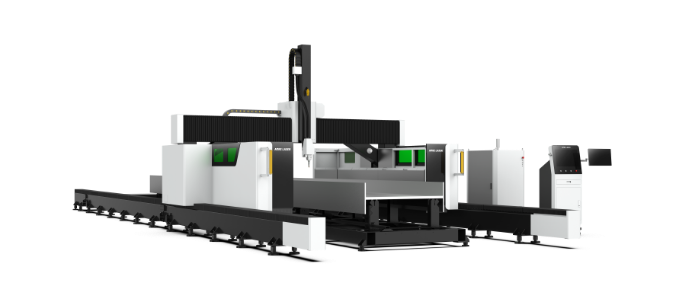

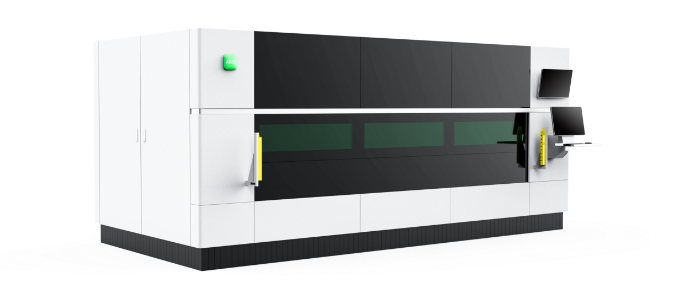

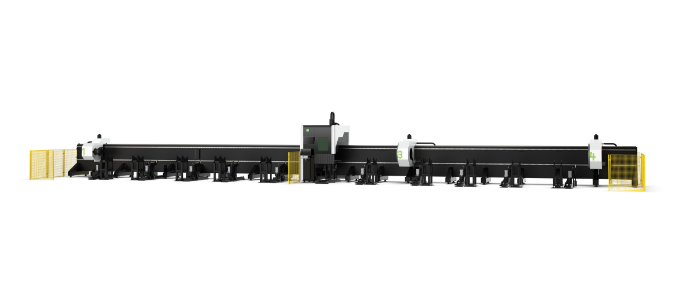

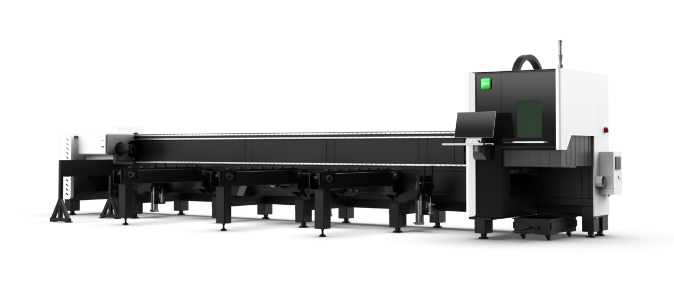

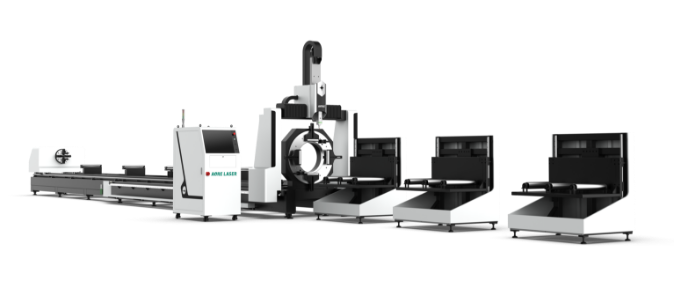

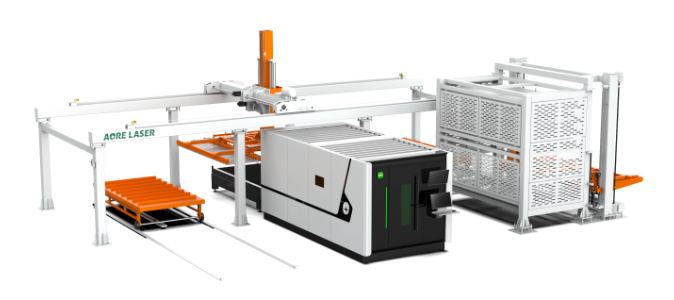

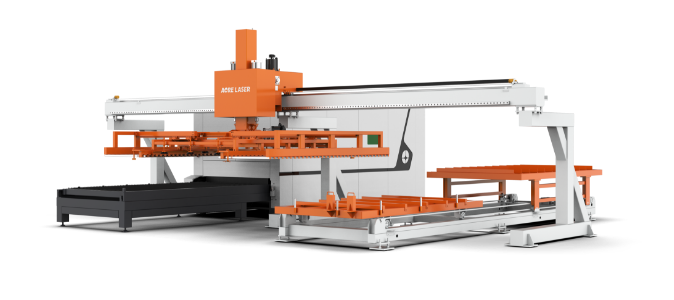

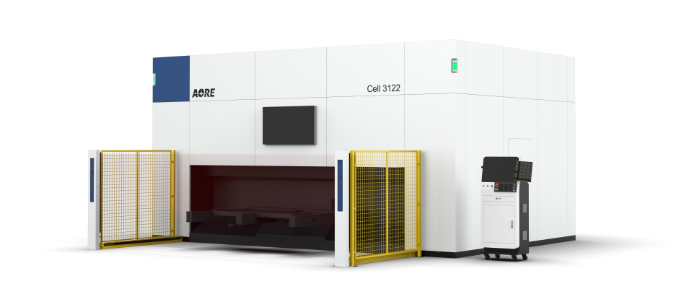

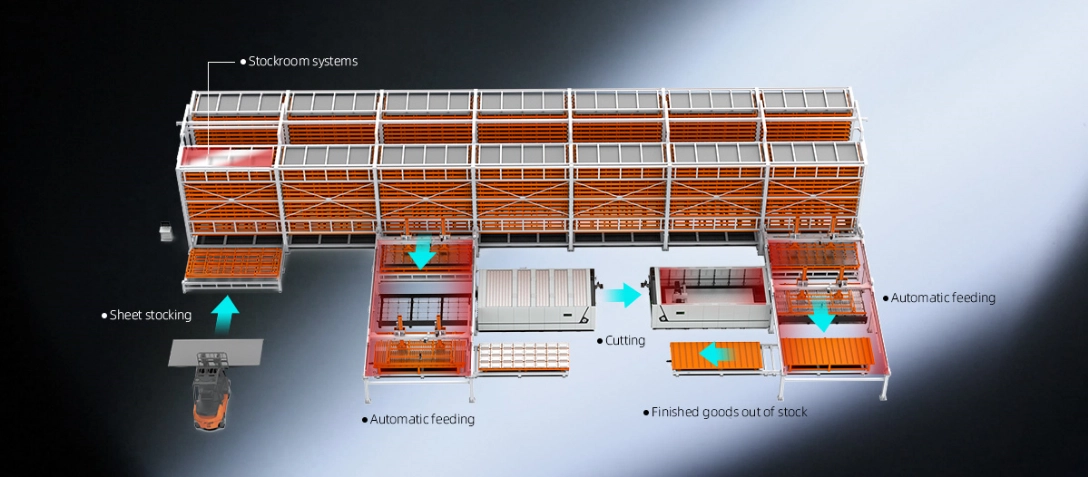

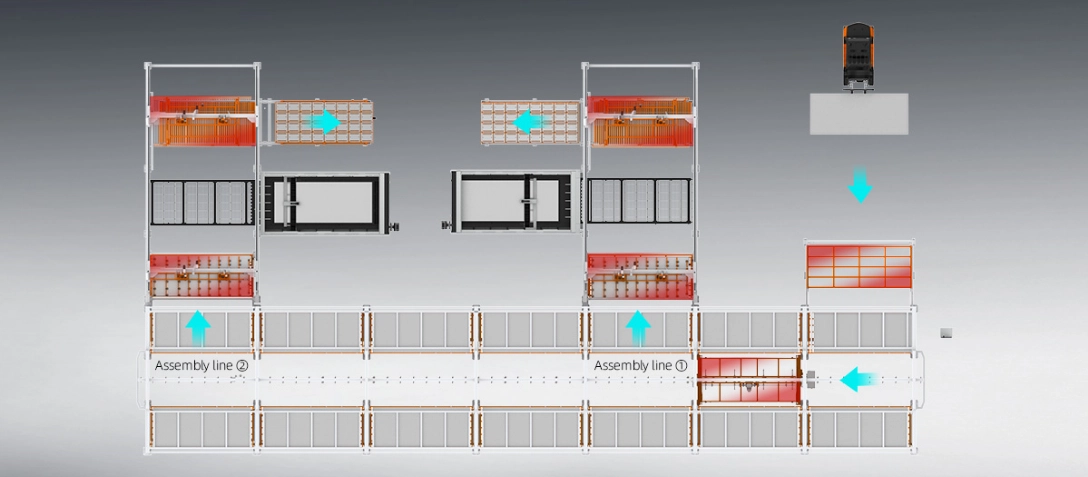

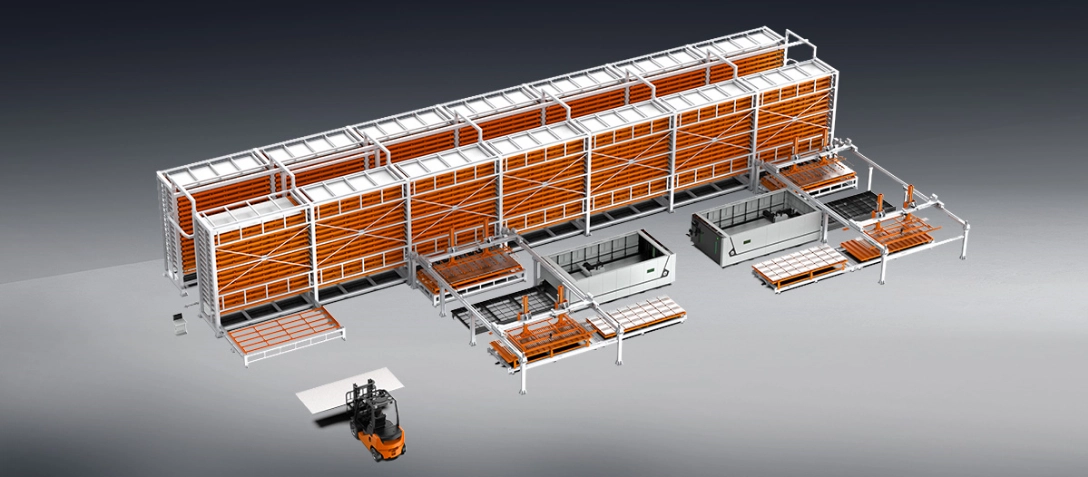

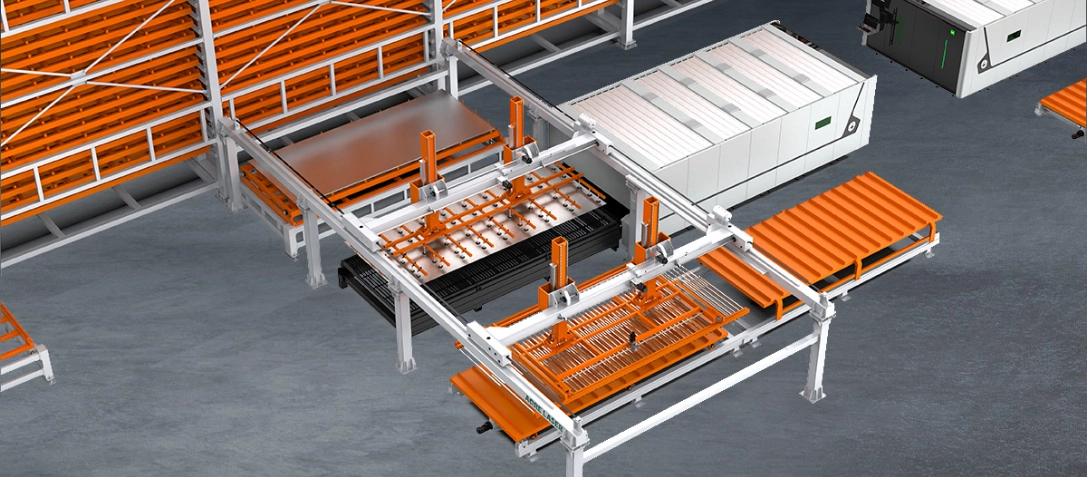

Multi-process integration

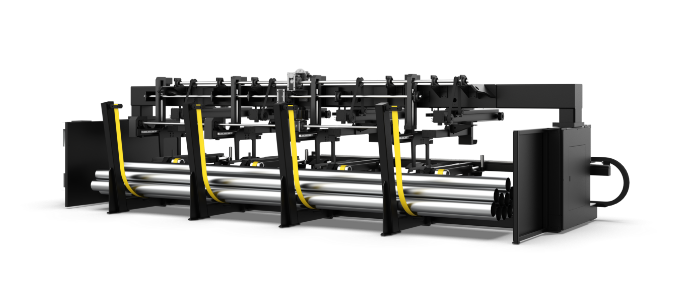

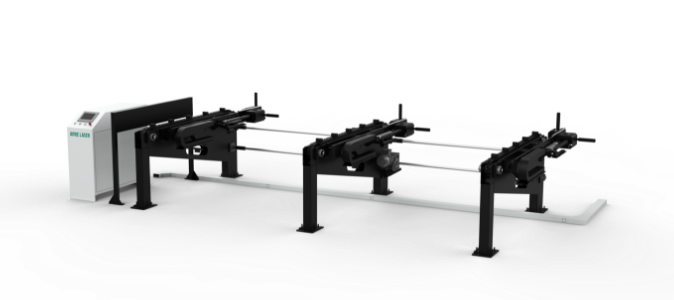

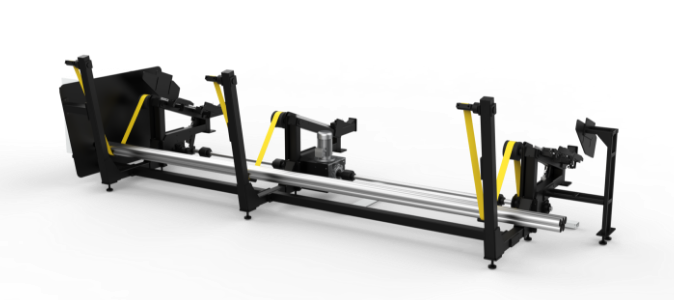

Covering from production scheduling, nesting, programming to raw material storage, loading, cutting, transferring of workpieces and waste materials after cutting, realizing fully automated production.

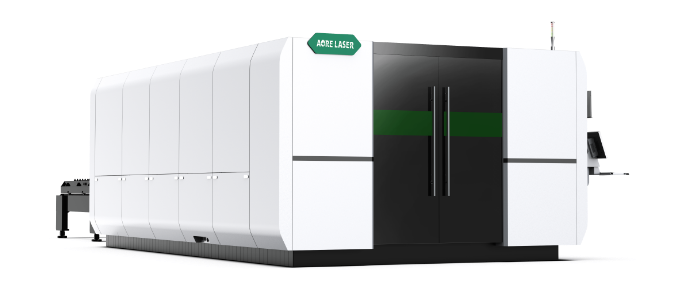

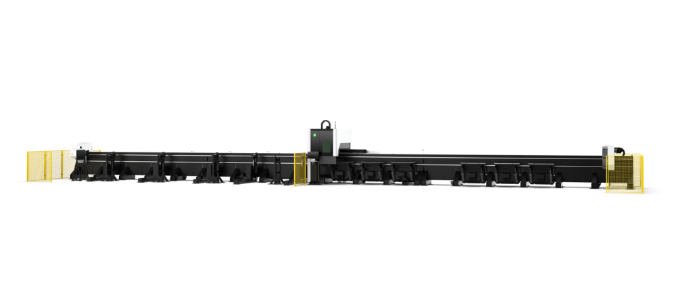

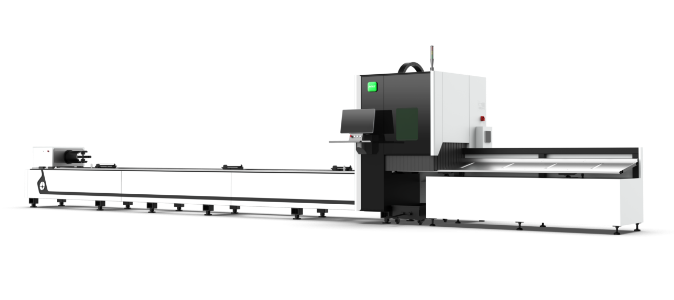

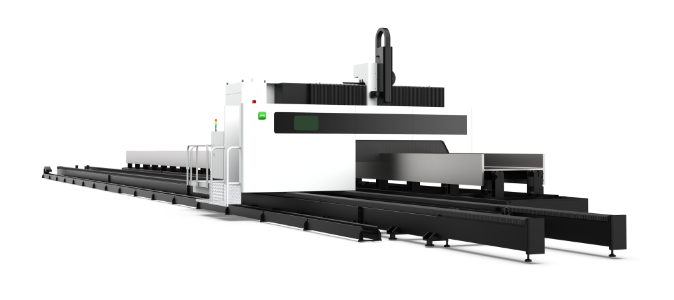

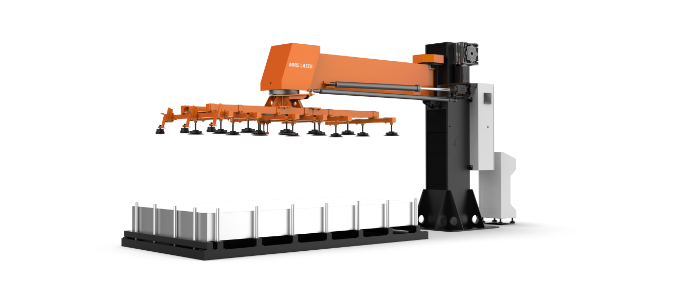

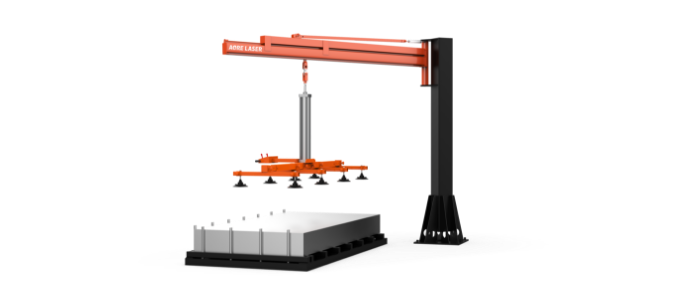

Digitalization

Automate the workflow, reduce labor costs and improve work efficiency.

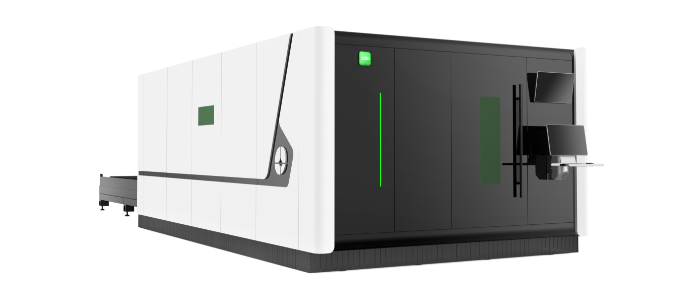

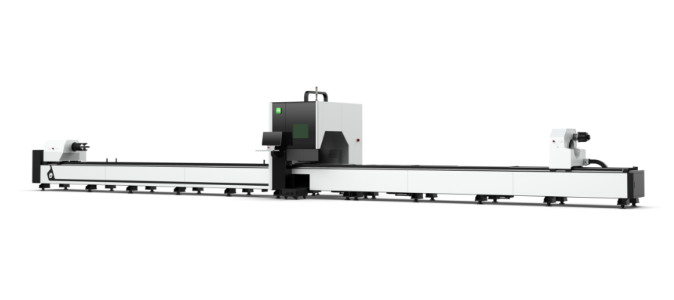

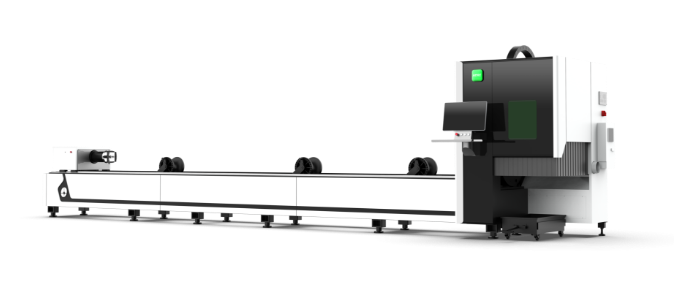

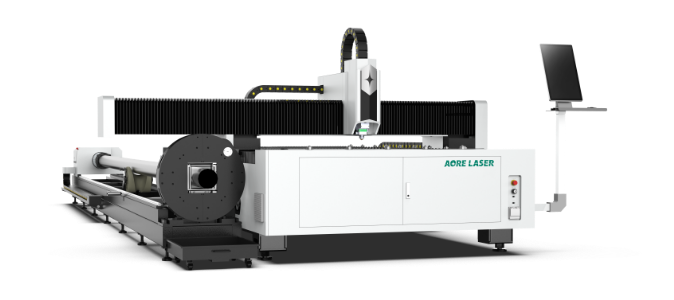

Networked

Realize real-time monitoring of the production process and data analysis, timely detection and resolution of problems, improve product quality.

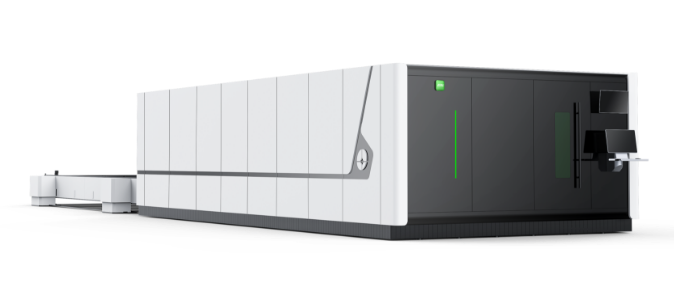

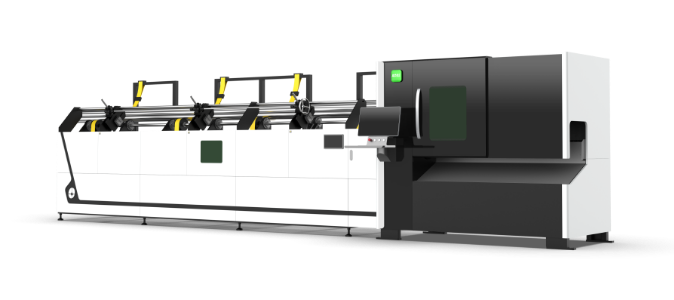

Intelligent

Optimize production information, reduce the production cost of the entire production line, improve the overall efficiency of collaboration.

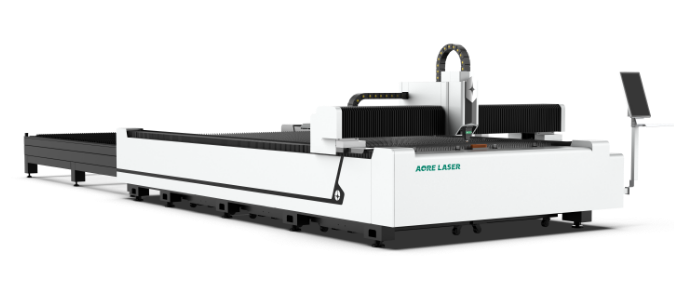

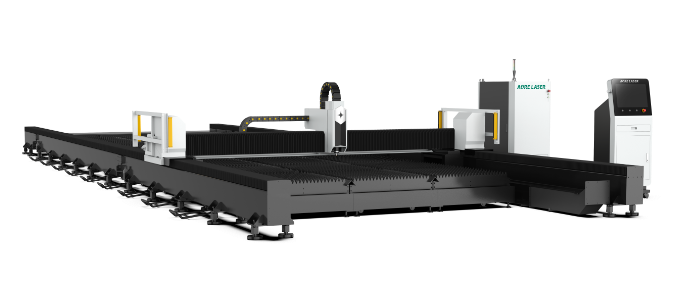

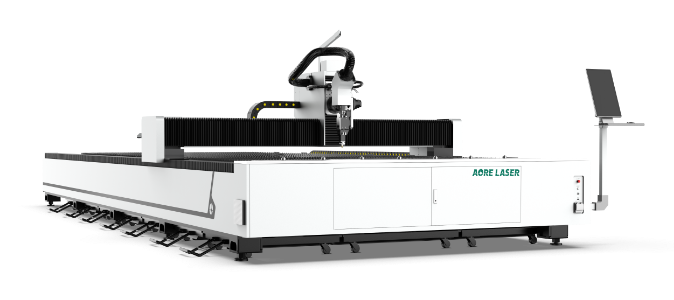

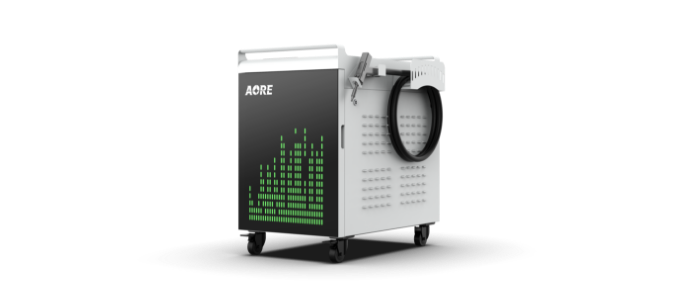

Our products are suitable for the industry

Our products are widely used in engineering machinery, petroleum pipeline, steel structure construction, building materials decoration, elevator manufacturing, fitness equipment, furniture kitchen and bathroom, advertising road signs and other industries.