Please select language

Inquiry

Tel

Inquiry

Tel

Large-diameter heavy-duty pipes and profiles are essential raw materials with wide-ranging applications in industries such as petroleum, chemicals, construction, energy, engineering, and machinery. However, the industry faces several challenges due to traditional processing drawbacks, increasing market competition, fluctuations in raw material prices, and changes in environmental protection policies.

Challenge 1: Inconsistent Quality

The processing of large heavy-duty pipes and profiles often involves custom, one-off production, leading to complex manufacturing processes. The quality of the final products can be affected by various factors including the quality of raw materials, production techniques, equipment precision, and worker skills. This complexity can lead to issues such as weak welds and dimensional inaccuracies. Some companies still rely on traditional plasma cutting methods, which can be limited by older equipment and varying levels of worker skill, resulting in inconsistent product quality.

Challenge 2: Delays in Delivery

The customized production of heavy-duty pipes and profiles requires careful management of numerous details, specifications, and serial numbers. A mistake in one area can have a cascading effect on the entire production process, making it difficult to trace and correct errors. Sorting components can be particularly challenging when done manually, and achieving 100% inspection of heavy and diverse parts becomes nearly impossible. This often leads to delays in delivery, exposing companies to risks such as penalties for contract breaches or loss of customer trust.

Challenge 3: High Production Costs

The cost of raw materials in the processing of heavy-duty pipes and profiles is typically a significant portion of overall expenses. Prices for materials like steel are subject to substantial fluctuations due to international market conditions and domestic supply and demand dynamics. Additionally, rising labor costs contribute to increasing overall production expenses. Errors in cutting or layout can lead to material waste, further driving up costs.

Challenge 4: Safety Concerns

The processes involved in handling heavy-duty pipes and profiles can generate a lot of smoke and dust, leading to environmental pollution from cutting fluids and significant noise pollution. Traditional processing methods, such as plasma cutting, carry inherent safety risks that can lead to serious accidents, endangering worker safety.

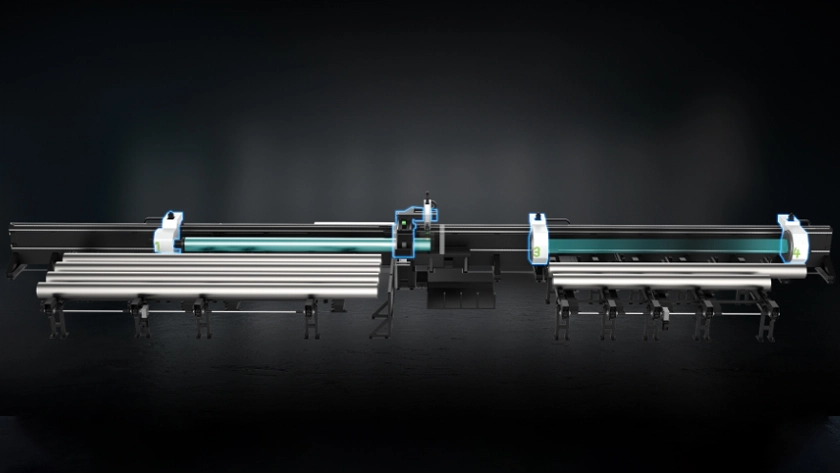

To address the efficient processing needs of large-diameter heavy-duty pipes and profiles, AORE has developed a flagship heavy-duty four chuck laser cutting machine. This machine features high load capacity, strong stability, a wide cutting range, and advanced automation, significantly reducing labor intensity while increasing processing efficiency and lowering costs.

Feature 1: High Load Capacity and Stable Cutting

The heavy-duty side-mounted bed structure ensures a low center of gravity and strong load capacity, while the four chuck clamping system, combined with multi-point supporting mechanisms, guarantees stable cutting for heavy-duty pipes and profiles weighing up to 3 tons.

Feature 2: Wide Range of Cutting Types

This machine can efficiently cut pipes ranging from Φ30 to 550 mm and square tubes from 30×30 to 550×550 mm, accommodating various profiles such as round pipes, square pipes, angle steel, channel steel, rectangular tubes, H-beams, oval pipes, and I-beams.

Feature 3: Simultaneous Cutting and Material Processing

The four chuck "2+2" processing mode allows for simultaneous loading and cutting, dramatically improving production efficiency.

Feature 4: Zero Tail Material Cutting for Long Workpieces

With multiple clamping methods, the machine can move materials forward or backward during cutting, meeting the demands for cutting oversized and exceptionally long workpieces while achieving true zero tail material cutting.

Feature 5: Efficient Automatic Loading and Unloading

The machine features a horizontal loading and unloading structure with high load capacity, ensuring smooth and safe material handling. It can cycle materials more than twice as effectively as manual loading. Both the loading and unloading ends are equipped with highly sensitive independent servo supporting mechanisms to ensure stable loading and unloading of different profile and specialty pipes.

Feature 6: Static Cutting

For densely packed cutting shapes on heavy-duty pipes, the static cutting feature allows for processing without moving the pipes, significantly improving cutting precision and reducing power consumption.

Feature 7: Strong Equipment Expandability

Optional features such as multi-pipe loading and unloading as well as bevel cutting capabilities can be included to enhance the machine’s processing capabilities, meeting even more cutting needs for customers and helping to reduce costs and increase efficiency in production.

AORE's flagship TZ series is dedicated to meeting the high-efficiency processing needs of heavy-duty pipes and profiles, empowering industries such as steel structure, engineering machinery, metal processing, pipeline construction, bridge engineering, and construction with powerful cutting capabilities and an outstanding processing experience.