Please select language

Inquiry

Tel

Inquiry

Tel

Steel structure materials are gaining popularity across various industries due to their high strength, short construction timelines, lightweight nature, eco-friendliness, and ease of assembly. As the steel structure industry advances, competition intensifies, and production costs rise, processing requirements are shifting from single-process to integrated solutions. An increasing number of steel structure manufacturers seek equipment that can handle not only profile cutting but also accommodate the processing of sheets and tubes.

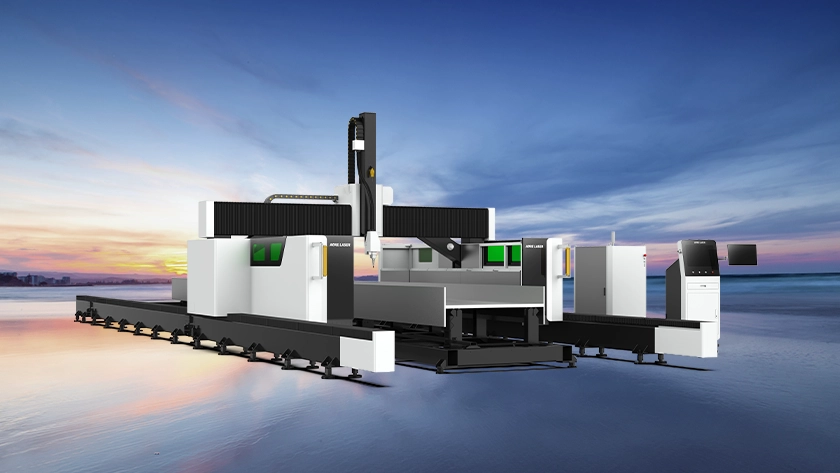

As a global expert in high-quality laser equipment applications, AORE Laser has introduced the GR-H all-in-one fiber laser cutting machine, drawing upon deep technical expertise and a comprehensive understanding of the steel structure industry's production processes and needs. The GR-H is designed to empower steel structure fabrication companies to reduce costs and improve efficiency.

All-in-One Solution for Steel Structure Processing

The GR-H is an all-in-one composite solution designed for the steel structure industry, capable of handling profiles, sheets, and tubes with ease. Its wide range of processing capabilities and versatile techniques allow it to perform one-stop processing of H-beams, I-beams, channel steel, angle steel, tapered beams, square tubes, round tubes, and sheets. The GR-H easily manages various cutting operations such as severing, beveling, hole-cutting, notching, and marking.

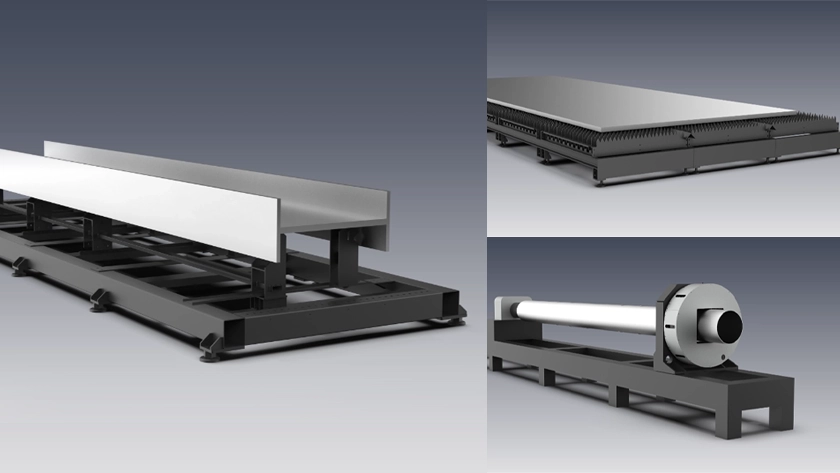

Profile Processing Range: 200x100 mm to 1500x500 mm

Sheet Processing Range: 3200 mm to 13,000 mm

Tube Processing Range: Φ15 to 1200 mm, 口15 mm to 550 mm

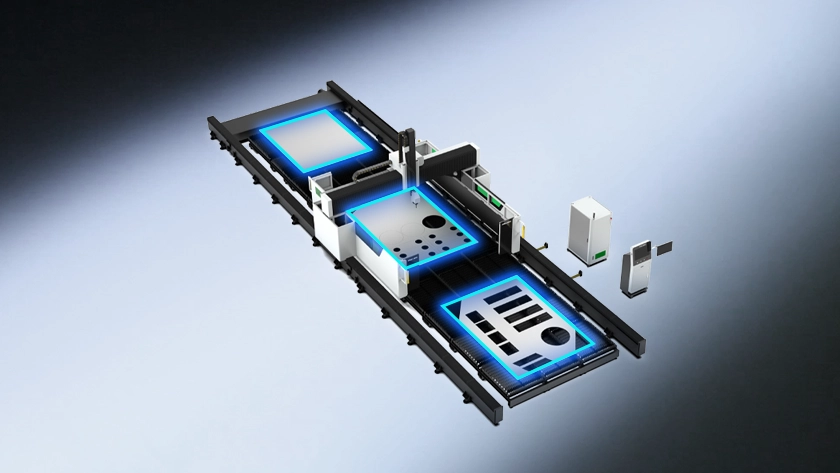

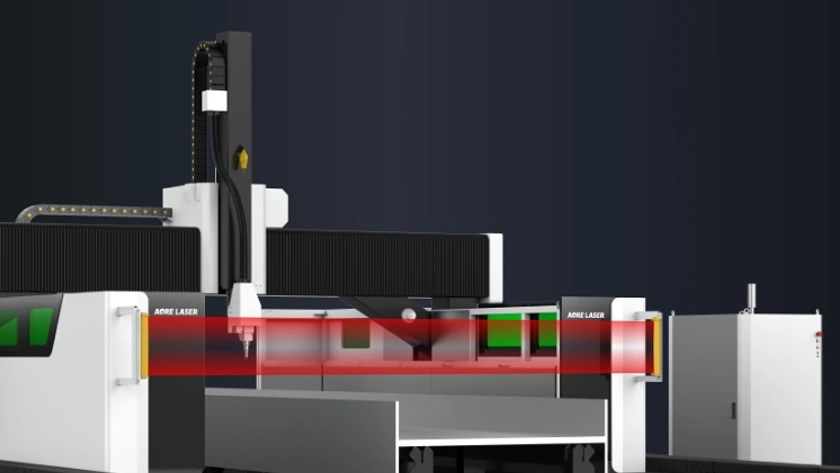

Multi-Position Processing Design for Enhanced Efficiency

The GR-H series features a gantry-style heavy-duty guide rail design that enables multi-position partitioned material processing, allowing simultaneous cutting and loading/unloading. For example, while profiles are being cut in one area, pre-processed tubes can be unloaded, and sheets can be prepared for loading in another. This setup supports an efficient cycle of cutting, loading, and unloading, significantly reducing production time and labor costs while boosting production efficiency.

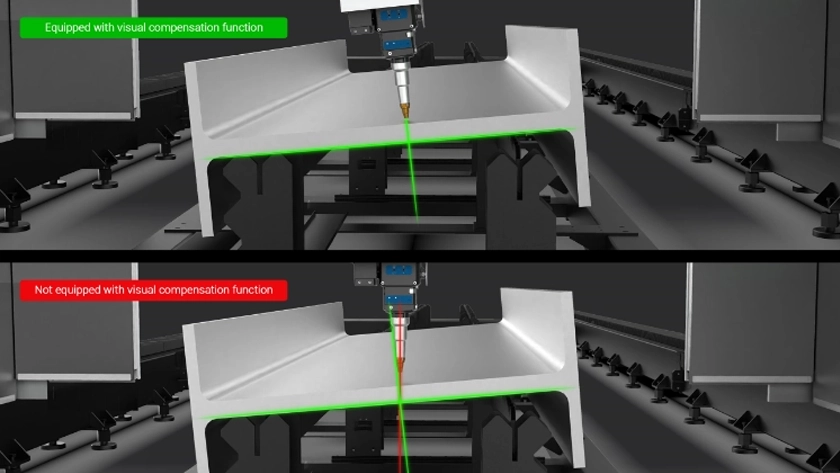

Intelligent Scanning and Simplified Profile Processing

To ensure high-precision profile processing, the GR-H is equipped with contour scanning and positioning functionality. It can detect profile deformation and misalignment in real-time, using visual compensation to optimize cutting paths, preventing issues such as misaligned cuts, off-angle holes, and cutting head collisions. This ensures efficient, precise processing, making profile cutting more straightforward.

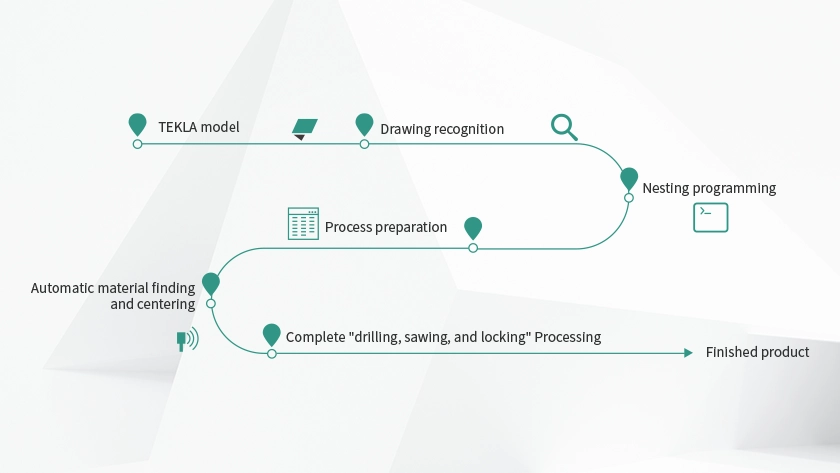

Professional Profile Cutting System with Tekla Compatibility

The GR-H series is equipped with a professional profile cutting system that seamlessly integrates with Tekla’s intelligent nesting software, enabling automated drawing analysis, sorting, and precise cutting. This integration significantly aids secondary profile processing, reducing labor costs and maximizing productivity.

Multiple Safety Features for Secure Production

To ensure safe operation, the GR-H machine's processing area is equipped with protective enclosures that prevent hazards such as splattering slag and laser radiation. Additionally, safety light curtains along the beam’s movement path continuously monitor for potential safety risks, preventing injuries caused by improper operation.

All-in-One processing, empowering steel structure fabrication. With its ability to process profiles, sheets, and tubes in a single platform, the GR-H supports steel structure enterprises in transitioning from traditional production methods to intelligent manufacturing. This innovation not only enhances a company's competitiveness but also injects new vitality into the modernization and sustainability of the entire steel structure industry. The GR-H series, All-In-One fiber laser cutting machine, is set to unlock greater efficiency in profile processing, providing comprehensive, high-efficiency support for the steel structure sector’s manufacturing advancements.